Matt and polished porcelain tiles can be used on indoor floors and indoor and outdoor walls.

Frequently asked questions

Intended use

01

Where can POLISHED and MATT porcelain tiles be used?

02

Where can POLISHED porcelain tiles be used in COMMERCIAL SPACES?

Polished porcelain tiles can be laid in medium-traffic commercial spaces unless local regulations require special non-slip surfaces. Medium-traffic commercial spaces include: restaurants, offices, shops, public restrooms, public offices, hotels except for foyers, business lounges, etc. with the exception of mandatory passageways and areas subject to the transit of trolleys with hard wheels or highly concentrated loads.

03

WHERE CAN MATT, OUTDOOR, AND GRIP FINISHES (EXCEPT THOSE WITH 6 MM THICKNESS) BE USED?

Porcelain tiles with matt, outdoor and grip finishes can be laid in heavy-traffic commercial spaces. Heavy-traffic commercial spaces include: malls, airports, places of worship, schools, museums, squares, hospitals, hotels - foyers, undergrounds, train stations, etc.

04

Where can white-body SINGLE-FIRED tiles be used?

White-body single-fired ceramic tiles can be used as wall tiles in indoor spaces.

05

Is it possible to lay single-fired mosaics in SWIMMING POOLS and SHOWER TRAYS?

Single-fired mosaics can be used as shower trays as long as they have the right slopes and the ceramic tiles are never completely submerged by water. Atlas Concorde does not recommend the use of single-fired mosaics in swimming pools. All porcelain tiles in the Atlas Concorde range are well-suited for this type of application.

06

Can porcelain tiles be used as OUTDOOR paving for vehicles?

Any type of porcelain tile (except those with a 6 mm thickness) can be used for driving surfaces as long as they are laid on a properly designed substrate using the "double buttering" technique, that is, spreading the adhesive on both the substrate and the back of the tile. This ensures a complete wetting of the back of the tile and ensures the absence of voids between the tile and the substrate, which can be a cause of breakage in the case of impact and/or concentrated loads.

Specifically:

Porcelain tiles with a thickness greater than or equal to 20 mm with an anti-slip finish can be used in industrial and commercial driving areas (aprons, public parking lots, gas stations, pavements traversed by forklifts, pallet trucks, tractor-trailers, buses, industrial platforms, etc.). Please note, porcelain tiles laid dry (on grass, sand, or gravel) or raised cannot be driven over by vehicles but only walked on (2022 catalog).

Porcelain tiles having an 8 or 9 mm thickness with non-slip finish can be used for residential driveways (driveways of private homes, apartment complex parking lots, indoor garages, etc. that are only traversed by cars).

07

Can porcelain tiles be used for OUTDOOR paving? What are the non-slip characteristics of outdoor paving?

For uncovered outdoor paving, Atlas Concorde suggests porcelain pavers with Textured, GRIP, Outdoor finish that meet (unless there are special regulations) at least the R11 coefficient according to DIN 16165 ANNEX B (EX DIN 51130) (for uncovered outdoor spaces). For covered outdoor applications, it is suggested to use porcelain tiles with an R10 coefficient in accordance with DIN 16165 ANNEX B (EX DIN 51130) R10.

08

What type of porcelain tiles is best for large spaces?

In large, high-traffic architectural projects, Atlas Concorde recommends porcelain tile collections with a Matt or Matt Sensitech finish.

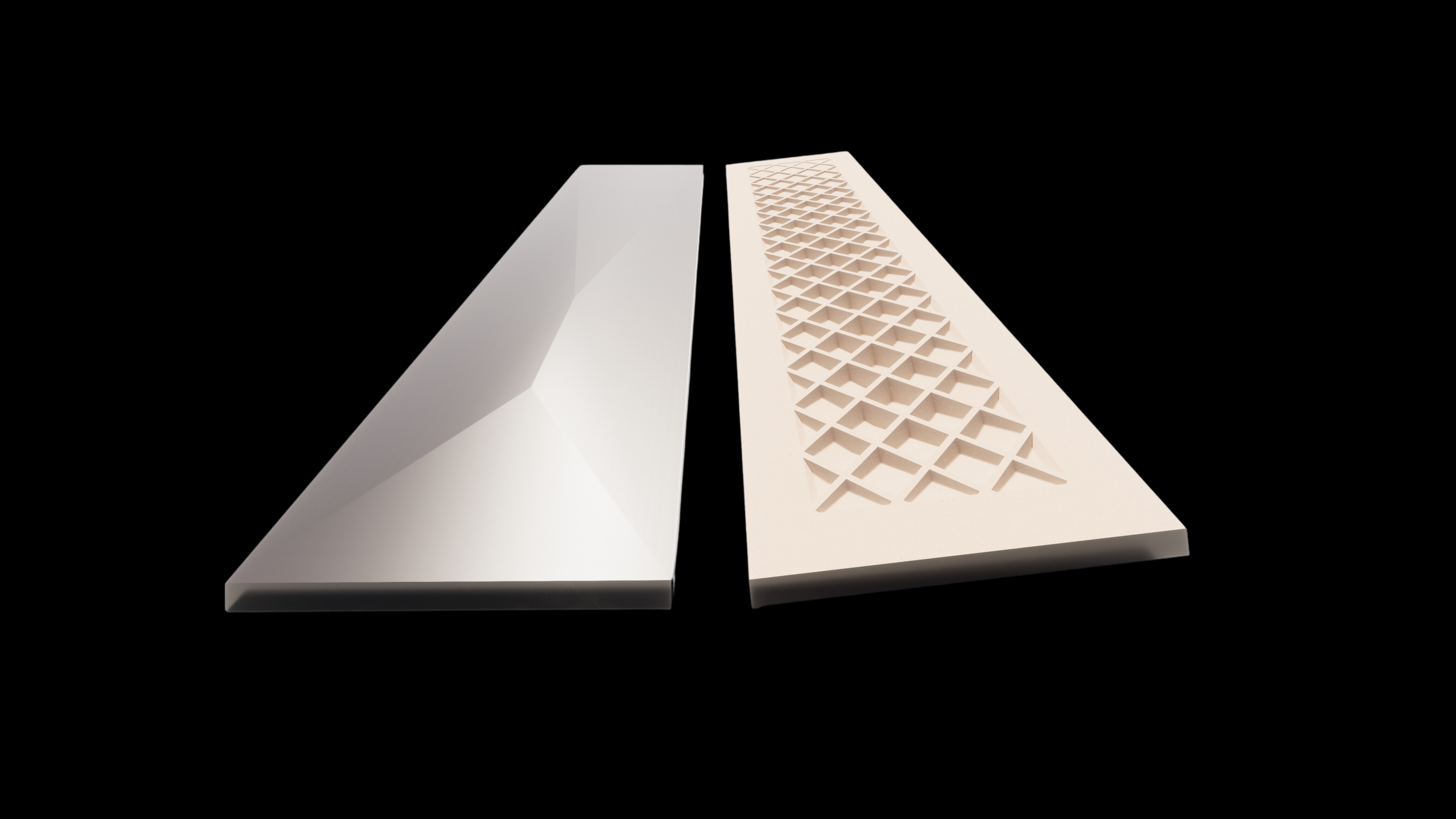

Extensive research by the laboratories of Atlas Concorde has led to the development of Sensitech, the porcelain surface made with a production method patented in Italy. A high-tech surface for interiors that combines high slip resistance with an unrivaled soft touch, which also makes it resistant to dirt and easier to clean. With Sensitech the meaning of surface evolves and takes on a reassuring, protective, and pleasantly refined touch, making architectural spaces increasingly comfortable and rewarding.

Laying of porcelain tiles

01

Is it possible to LAY ceramic tiles without JOINTS? What are the recommended joint widths?

Atlas Concorde does not recommend installation without joints. The width of the joints should be determined during the design stage, mainly based on:

The dimensional characteristics of the tiles (rectified or unrectified)

The type of substrate

The intended use (indoor/outdoor floor or indoor/outdoor wall)

The presence of codes and/or laying regulations in force in the country where the ceramic tiles will be installed

02

How do I choose the COLOR of the GROUT to use with a certain tile?

Atlas Concorde staff are always available to recommend the most appropriate grout for each item, providing grout codes based on the ceramic tiles being installed.

03

In a construction site, how should the ceramic tiles be PROTECTED after installation and before handover to the final customer?

In the period between completion of installation and handover to the final customer, the ceramic tiling (especially in the case of polished or velvet finish) must be: • Kept clean and free of cement, sand, mortar, and any other material that could cause staining and/or surface abrasion. • Protected against damage or staining caused by other construction workers (painters, electricians, carpenters, etc.)

04

Where should the installation waste be disposed of?

The debris from broken tiles are inert (non-reactive, chemically and physically stable, resistant to prolonged exposure even under extreme conditions from a thermal, hygrometric and chemical point of view) that can be disposed of without any particular risk, and can also be used to produce substrates, etc.

Atlas Concorde recommends that broken tiles be taken to the nearest waste separation area for proper, environmentally friendly disposal.

05

How many tiles should I order?

Atlas Concorde staff are always available to advise on the amount of materials to be ordered.

In general, to calculate the number of tiles needed for the project, you must:

Know the total surface area to be covered.

Have already determined the technique, laying pattern (straight course, staggered, etc.) and joint size.

A certain amount of scrap must then be considered, since even a delivery of first-rate tiles may contain some defective pieces (current standards consider 5% defective tiles in a first-choice batch permissible) and some tiles will have to be cut or drilled. Furthermore, it is a good idea to keep some spare tiles after the installation is completed for any repairs that become necessary.

Therefore, Atlas Concorde recommends ordering an average of 10-15% more tiles than the area of the surface to be tiled. The quantity should be carefully evaluated at the time of ordering, since if a later order becomes necessary the product in stock may not be a perfect match for the tiles used up to that time.

06

What recommendations should be followed when laying porcelain tiles on HEATED FLOORS?

After the screed curing period, which varies depending on the type of binder used, the heating system should be turned on to make sure it works properly and to complete the curing. For installation:

Use deformable improved cement-based adhesives (class C2E-S1 according to EN 12004).

Use the "double buttering” technique.

Maintain at least 3 mm of joint regardless of the tile format used.

Furthermore, a compressible material such as expanded polystyrene with a 1 cm thickness should be placed around the entire perimeter of the room and around pillars, columns, and floor elevations, and expansion joints measuring no less than 5 mm in width should be made in the screed and carried over into the flooring at least every 20-25 m² (almost never required in residential properties).

This is simply a rough guideline. We suggest that you always follow the recommendations of designers or screed manufacturers.

07

What are the recommendations to be followed when LAYING STEPS and L-SHAPED CORNER ELEMENTS?

When laying it is necessary to leave 3-4 mm of shifting space for the bullnose to prevent the breakage of the piece caused by the settling of the structure due to sagging or sharp temperature fluctuations.

It is also recommended that an elastic material be used for grouting the joints around the bullnose.

08

What ADHESIVES should be used when laying PORCELAIN and SINGLE-FIRED TILES?

The use of the right adhesive is of paramount importance for installation. Atlas Concorde recommends following the directions of the best adhesive manufacturers for ceramic tile installation.

In general, the selection of the most appropriate adhesive is based on the following factors:

Type of substrate

Type and format of the tiles

Intended use (floor/wall; indoor/outdoor)

Climatic conditions at the time of installation

Time until the tiles are subjected to normal use

09

Laying tips - Floor and wall tiles

Before starting laying, it is recommended to make sure that the supporting surface is sufficiently cured, flat, and well cleaned.

LAYING SUGGESTIONS

Before starting laying, it is recommended to make sure that the supporting surface is sufficiently cured, flat, and well cleaned.

RECOMMENDED ADHESIVES

The use of the right adhesive is of paramount importance for installation. We recommend following the directions of the best adhesive manufacturers for ceramic tile installation. In general, the selection of the most appropriate adhesive is based on the following factors:

Type of substrate

Type and format of the tiles

Intended use (floor/wall; indoor/outdoor) of the ceramic tiles

Climatic conditions at the time of installation

Time until the tiles are subjected to normal use

(*) For large format tiles laid at heights greater than 3 meters, some international standards stipulate that the installation be done using both adhesive and a mechanical hook system to be chosen based on the weight of the tile, its height, and site conditions.

When laying in low temperatures or if it is necessary to use the tile surface as soon as installation is completed, the use of improved cement-based adhesives with rapid setting (Class C2F - EN 12004) is preferred.

For more detailed information about this, please, consult page 426 of our General Catalog.

APPLICATION OF ADHESIVES AND LAYING TILES: EXPERT TIPS

Installation should be performed by qualified personnel using the proper tools. The laying of the material should be checked before the adhesive is dry so that any corrections can be made. In any case, Atlas Concorde does not recommend installation without joints or joints smaller than 2 mm. When laying tiles with a side longer than 60 cm and in any case for commercial indoor environments or outdoors it is essential to spread the adhesive using double buttering, applying the adhesive in a linear method parallel to the short side both on the substrate and on the back of the tile, thus ensuring perfect adhesion between the tile and substrate. In order to minimize uneven tiles both on the floor and on the wall, it’s best to use “easy-laying systems” with spacers and levelers that can be equipped with anti-chip and anti-scratch baseplates when laying white-body glazed wall tiles and/or porcelain tiles with a polished finish. For wall tiles with three-dimensional surfaces we recommend the use of screw leveling systems as an alternative to wedge systems.

RECOMMENDED GROUTS

It is important to use the right grout depending mainly on the intended use of the ceramic surface. We recommend following the directions of the best joint grout manufacturers.

For more detailed information about this, please, consult page 426 of our General Catalog.

REMOVAL OF EXCESS GROUT

To properly and easily remove excess grout, it is recommended to follow the grout manufacturer's instructions. In general, the following is recommended.

Cement-based grouts

When the grout becomes opaque (usually after 10 to 20 minutes), wipe with a hard cellulose sponge in a direction diagonal to the joints. It is important to respect these times so as not to risk removing grout from the joints.

Epoxy grouts

While the mixture is still fresh, wet the surface thoroughly by emulsifying with a Scotch-Brite® pad, taking care not to remove grout from the joints. Liquid grout residue can be removed with a hard cellulose sponge (to be replaced if too heavily impregnated with resin). It is essential to remove the epoxy grout promptly before it begins to harden, as it is extremely difficult to remove when fully dry. If the epoxy putty has already started to harden, try adding 10% alcohol to the washing water.

010

What is the straight course laying pattern for rectangular tiles

For straight courses of rectangular formats, the maximum offset between tiles must not exceed 1/3 of the length of the adjacent side.

011

Laying tips – Walls

Before starting laying, it is recommended to make sure that the supporting surface is sufficiently cured, flat, and well cleaned.

RECOMMENDED ADHESIVES

The use of the right adhesive is of paramount importance for installation. We recommend following the directions of the best adhesive manufacturers for ceramic tile installation.

In general, the selection of the most appropriate adhesive is based on the following factors:

• Type of substrate

• Type and format of the tiles

• Intended use (floor/wall; indoor/outdoor) of the ceramic tiles

• Climatic conditions at the time of installation

• Time until the tiles are subjected to normal use

For more detailed information about this, please, consult page 426 of our General Catalog.

(*) For large format tiles laid at heights greater than 3 meters, some international standards stipulate that the installation be done using both adhesive and a mechanical hook system to be chosen based on the weight of the tile, its height, and site conditions.

When laying in low temperatures or if it is necessary to use the tile surface as soon as installation is completed, the use of improved cement-based adhesives with rapid setting (Class C2F - EN 12004) is preferred.

APPLICATION OF ADHESIVES AND LAYING TILES: EXPERT TIPS

Apply the adhesive on the substrate using a trowel with appropriate toothing.

Exert solid pressure on the tiles to make sure that at least 70% of the total surface area is wet.

When laying tiles in commercial indoor spaces or outdoors it is essential to apply the adhesive using double buttering, thus ensuring the absence of gaps between the tile and the substrate.

RECOMMENDED GROUTS

It is important to use the right grout depending mainly on the intended use of the ceramic surface.

We recommend following the directions of the best joint grout manufacturers.

For more detailed information about this, please, consult page 426 of our General Catalog.

REMOVAL OF EXCESS GROUT

To properly and easily remove excess grout, it is recommended to follow the grout manufacturer's instructions. In general, the following is recommended.

Cement-based grouts

When the grout becomes opaque (usually after 10 to 20 minutes), wipe with a hard cellulose sponge in a direction diagonal to the joints. It is important to respect these times so as not to risk removing grout from the joints.

Epoxy grouts

While the mixture is still fresh, wet the surface thoroughly by emulsifying with a Scotch-Brite® pad, taking care not to remove grout from the joints. Liquid grout residue can be removed with a hard cellulose sponge (to be replaced if too heavily impregnated with resin). It is essential to remove the epoxy grout promptly before it begins to harden, as it is extremely difficult to remove when fully dry. If the epoxy putty has already started to harden, try adding 10% alcohol to the washing water.

012

What is the straight course laying pattern for rectangular tiles

For straight courses of rectangular formats, the maximum offset between tiles must not exceed 1/3 of the length of the adjacent side.

013

Guidelines on the correct and safe handling of tiles and packaging

No special storage measures are necessary, except for protection against impacts that could cause the material to break.

It’s best to store the product in its original packaging until its use, if possible well covered in the event of prolonged exposure to the open air.

Handling precautions:

For rectified single-fired wall tiles take great care not to bump the very fragile edges.

For tiles with a polished or velvet finish, take great care when removing them from the box, making sure not to scrape the back of one tile on the top of the one underneath, irreversibly scratching the tile’s surface before it is even used.

Protective gloves must be worn to avoid accidental injury caused by any breakage of the pieces inside the boxes.

Avoid any excessive effort when handling the packaged tiles, so always read the maximum weight of the box.

No special storage measures are necessary, except for protection against impacts that could cause the material to break.

It’s best to store the product in its original packaging until its use, if possible well covered in the event of prolonged exposure to the open air.

Handling precautions:

• For rectified single-fired wall tiles take great care not to bump the very fragile edges.

- For polished tiles, be very careful when removing them from the box, strictly avoiding rubbing the rough back of the tile against the polished surface of those underneath in order not to irreversibly scratch them.

Protective gloves must be worn to avoid accidental injury caused by any breakage of the pieces inside the boxes.

Avoid any excessive effort when handling the packaged tiles, so always read the maximum weight of the box.

Since the installer is the professional who first "sees" and "handles" the tiles, before laying the tiles the installer must inform the customer and the designer of any obvious defects (quality, tone, etc.).

Given that varied shading is a characteristic of a number of tile collections, verification and knowledge of the degree of variable shading (V-SHADE) of the tiles to be installed is required.

When installing polished or velvet finish tiles, do not mark the shiny surface with pencils and/or permanent markers.

While it isn’t necessary to wet the tiles before laying them, in the case of very dusty surfaces it’s still advisable to quickly wash them in clean water.

014

Guidelines on the safe cutting of tiles.

Tools for linear or diagonal cuts (with any type of angle) depend on the type of ceramic material:

• Glazed tiles (white-body single-fired tile or glazed porcelain tile)

• Colored-body porcelain tiles

On-site cutting operations

1) Linear or diagonal cuts

For linear or diagonal cuts (with any type of angle) it may be sufficient to use manual tile cutters:

with adaptable discs having the right diameter and/or material for the type of tiles to be cut (glazed porcelain and/or single-fired).

For precise cuts of white body tiles it’s possible to use common nippers for glazed and/or porcelain tiles:

If dry manual tile cutters don’t achieve an optimal cut, we recommend the use of electric cutters with water cooling:

slowing the speed of forward movement when near the tile’s edge.

2) Circular holes

The tools for making circular holes depend on the type of tile (white body single-fired and/or porcelain) and whether the hole is made before or after installation.

To make circular holes in glazed tiles before laying, it’s best to use a hole-cutter bit on a common electric drill without percussion (maximum recommended speed of 800 rpm), working from the unglazed back of the tile.

To make circular holes in glazed tiles after laying, use a wall or concrete hole-cutter bit on a common electric drill without percussion, first using a screwdriver to make a starting hole in the glaze.

To make circular holes in porcelain tiles before laying, use water-cooled diamond hole-cutter bits on a common electric drill without percussion (maximum recommended speed of 900 rpm for thicknesses up to 95 mm, 450 rpm for larger thicknesses), working on the front surface of the tile, possibly equipped with a guide.

To make circular holes in porcelain tiles after laying, use water-cooled diamond hole-cutter bits on a common electric drill without percussion, equipped with a suction cup to make vertical holes in a set point, making sure the cutter doesn’t shift.

3) Quadrangular holes

Regardless of the type of tile, start by drilling circular holes near the corners of the hole following the instructions in point 1.2, and then connect them with linear cuts using dry angle grinders with a disc that’s appropriate for the tile type:

This will relax the stress at the corners of the cut tile.

4) Cutting tiles around objects

To shape floor or wall tiles positioned near elements such as walls, pillars, and so on, all the instructions detailed above for cuts and holes must be applied.

If a right-angle cut is needed along the perimeter of the room and around pillars, columns, and floor elevations, make sure the cut is made to avoid cracks in the tiles after installation, as this is where stress points and cracks develop.

Identification of hazards

The product is inert, and therefore in normal conditions of use does not pose any danger to health or the environment.

During cutting, crystalline silica (SiO2) dust can be released into the air, which is why it’s best to perform these operations using wet methods or using dry manual tile cutters in a ventilated space.

Any exposure to dust in the case of dry cutting with a grinder must be controlled and minimized using suction and/or forced ventilation systems.

Safety precautions:

Respiratory protection: Use appropriate respiratory protection.

Eye protection: Use protective eyewear against flying particles and/or tile chips.

Hand protection: We recommend the use of gloves for mechanical protection to avoid accidental cuts caused by any broken pieces.

Atlas Concorde tiles are not flammable or combustible. In the event of a fire in the immediate vicinity there is no limitation on the method used to extinguish it.

Maintenance and cleaning of ceramic tiles

01

How should the PORCELAIN TILES BE CLEANED FOR THE FIRST TIME when installation is completed?

Washing after installation is a critically important step for all subsequent maintenance. A final cleaning is performed to remove any residues of installation and normal job site dirt such as mortar, glue, paint, and so on. The job site is considered completed when it is cleared of any work tools/materials.

To reduce the risk of damage to the tiled surface, it is necessary to protect it and avoid the presence of abrasive materials. After a few days, remove any work-related residues with a commercial sponge such as Scotch-Brite® or with a scrub brush or single brush (for large surfaces).

For wall tiles, use a mild detergent diluted in warm water. For floor tiles, use a buffered acid detergent diluted as appropriate for the type of surface (smooth or textured). It is important to protect any marble or metal inserts with adhesive tape beforehand. Then rinse thoroughly with clean warm water until any streaking or residue in the crevices is removed. If necessary, repeat acid washing at higher concentrations unless marble or metal inserts are present. Avoid using diluted hardware acids.

02

How should the FIRST CLEANING of DECORS and INSERTS with special applications (gold/silver) be done?

The materials used for these decors have special characteristics typical of precious metals. Great care must be taken both when laying and especially when cleaning. Absolutely avoid the use of abrasive products that could scratch and damage the surface. For cleaning, Atlas Concorde recommends using only soft cloths with warm water and alcohol. For these reasons, no complaints and/or disputes can be accepted after the installation is completed. When cleaning these materials, do not use abrasive products at all, but simply cotton and alcohol or products specifically made for cleaning gold, copper, or shiny materials. In the event of silver oxidation, rub gently with a cloth to restore the original luster.

03

How should the porcelain tiles be maintained?

The use of a common mild detergent diluted in water is recommended. Avoid using acidic, alkaline, waxing and/or impregnating agents and steel wool (iron and steel sponges). For very dirty or particularly textured surfaces, use an alkaline-based detergent, rinsing after washing is complete. For large areas, the use of scrubber-dryers is recommended.

04

What if extraordinary maintenance is required on the porcelain tiles?

In the case of dirt that is resistant to ordinary cleaning, it is recommended to use a detergent specific to the type of dirt.

The cleanability of the materials varies significantly for different installation methods, conditions of use, types of surfaces, and environment. In general, the more a tile is non-slip, the more difficult it is to clean. A professional operator tasked with maintenance and cleaning should always conduct a preliminary check (possibly on an unlaid tile) for each type of job. In the event of particularly severe conditions of use (e.g., machine shops or environments with strong presence of oily residues and tire tracks), incorrect installation, or improperly performed cleaning, Atlas Concorde accepts no responsibility for the effectiveness of the cleaning and maintenance.

Atlas Concorde cannot be held responsible for events, damages or defects due to improper installation, negligent cleaning and maintenance, or inappropriate choice of the type of materials installed and adhesives used with regard to their intended purpose.

For more detailed information about this, please, consult page 426 of our General Catalog.

Ventilated facades

01

Up to what height can a ventilated facade be installed?

There are no regulatory limits on height, however it is a good idea to assess the context and calculate facade stresses accordingly and/or reinforce the slabs with safety nets.

02

Is it always necessary, and from what height, to protect the tile’s back with mesh?

It is advisable to protect the ceramic tiles with fiberglass mesh at any height. However, this choice should be assessed during the design phase based on the stresses of the facade, the intended use of the building, etc.

03

What size should the porcelain slabs be?

Rectangular sizes greater than or equal to 60x120 are best, both for esthetic factors and technical performance. Atlas Concorde offers a wide range of collections and formats suitable for ventilated facades. Special non-standard formats can also be produced on request.

04

What thicknesses should porcelain slabs have?

All thicknesses in the Atlas Concorde porcelain tile range can be used on ventilated facades. The greater weight but higher modulus of rupture of the 20 mm thickness is combined with a substructure capable of supporting greater weights, while a light weight and the possibility of undercut drilling allows products with a 9 mm thickness to be installed.

05

Can thin slabs be used on a ventilated facade?

The use of 6 mm thick slabs does not allow the use of certified undercut hole plugs to anchor the porcelain tile panel to the substructure.

In this case a fastening technique with structural adhesive or even better a hybrid, i.e., with both adhesive and mechanical restraints riveted to the metal profiles of the substructure, will have to be assessed during the design phase. It is the responsibility of the designer to provide the most secure attachment system based on the calculated loads and panel formats used.

06

Are there any energy savings? If so, can they be calculated?

Energy savings are one of the benefits of ventilated facades. Such savings can be calculated using the Finite Element Method based on the specific project.

07

Why are porcelain tiles better than other materials?

Atlas Concorde porcelain tiles are one of the most modern and suitable materials for use as a lightweight (< 30 kg/m²) facing in ventilated facade systems.

Indeed, they combine high architectural content with durability and functionality.

Atlas Concorde porcelain tiles ensure:

RESISTANCE TO THE ELEMENTS (impervious to acid rain, to absorption of smog, resistant to discoloration by light and UV rays, resistant to temperature changes and frost, etc.)

HIGH RESISTANCE TO BENDING AND IMPACTS

LOW LINEAR THERMAL EXPANSION COEFFICIENT

EXCELLENT BEHAVIOR IN THE EVENT OF A FIRE

EASY SANITIZATION

08

What are the advantages of a metal structure over an adhesive for a facade?

Compared with an adhesive, the metal structure ensures the safety of the tile in any risky situations (aging, fire and/or other natural phenomena), in addition to all the benefits of thermal inertia, acoustics and protection of the building.

Raised flooring

01

What is it possible to conceal in the empty space beneath the tiles?

One of the main advantages of raised floors is the creation of a gap between the walking surface and the underlying slab. This space can be used as a technical compartment for wiring and tubing of all kinds (electrical, plumbing, air conditioning, security, communications, etc.) or it can be left empty, thus allowing for greater insulation of the room from the subfloor or to raise the floor to a specific height.

One of the main advantages of raised floors is the creation of a gap between the walking surface and the underlying slab. This space can be used as a technical compartment for wiring and tubing of all kinds (electrical, plumbing, air conditioning, security, communications, etc.) or it can be left empty, thus allowing for greater insulation of the room from the subfloor or to raise the floor to a specific height.

02

Why is it better to use Atlas Concorde porcelain tiles than other materials?

The use of Atlas Concorde porcelain tiles for raised floors is a guarantee of superior technical performance and originality in the esthetic refinement of the flooring. In fact, compared with other materials Atlas Concorde porcelain tiles give the raised floor greater resistance to foot traffic, wear, temperature changes, and dirt, combined with extreme ease of cleaning and unique esthetic versatility.

03

What are the advantages of a calcium sulfate support over a wood support?

Panels with a mineral core are suitable for design solutions involving significant loads, places that demand greater fire resistance or spaces where sound absorption is crucial.

04

Can it be laid outdoors?

Certainly. Atlas Concorde provides structural solutions suitable for the construction of raised floors for outdoor spaces such as terraces, landscaped gardens and parks, walkways, pool edges, patios, etc.

05

What formats are available?

Atlas Concorde indoor raised floors have structures with modular panels available in four different formats: 45×90 cm, 30×60 cm, 60×60 cm and 60x120 cm.

06

What is the maximum height of the floor?

The load-bearing structures of raised floors Atlas Concorde allow floors to be built at different heights, from a minimum of 12 mm up to more than one meter.

07

Can I use all flooring finishes?

Atlas Concorde raised floors can be made using any flooring finish. Depending on the stylistic and functional requirements of the target environment, you can choose any Atlas Concorde finish, from matt-satin to honed or polished.

08

Are there limitations with respect to the method used to wash the raised floor?

Thanks to the Atlas Concorde porcelain tile finish, raised floors can be cleaned and sanitized with ease using simple dry vacuuming and mopping, slightly dampened and well wrung. Atlas Concorde also recommends avoiding pooled water on the surface and side edges of the panels as much as possible, which, if absorbed, could damage the floor.

.png?cropw=3687.1812062937065&croph=2074.03942854021&cropx=85.93002622377622&cropy=229.9605714597902&cropmode=pixel&quality=75#)

.png?cropw=2955.4734265734264&croph=1662.4538024475523&cropx=218.73103146853146&cropy=289.05378059440557&cropmode=pixel&quality=75#)

.png?cropw=3715.8243006993007&croph=2090.1511691433566&cropx=249.9783216783217&cropy=197.73694274475525&cropmode=pixel&quality=75#)

.jpg?cropw=4096&croph=2304&cropx=0&cropy=389.0000000000003&cropmode=pixel&quality=75#)

.jpg?cropw=4096&croph=2304&cropx=0&cropy=215.39045431878446&cropmode=pixel&quality=75#)